In the realm of automotive engineering, every detail matters, no matter how small. Fasteners, those seemingly insignificant components, play a critical role in ensuring the safety, performance, and longevity of vehicles. This article delves into the world of fasteners, shedding light on their importance, types, and contributions to the automotive industry.

Table of Contents

The Significance of Fasteners in Automobiles

Fasteners are the unsung heroes that hold a vehicle together. They secure crucial components such as engine parts, chassis components, body panels, and interior elements. These components must withstand tremendous forces, vibrations, and extreme conditions while maintaining structural integrity. Fasteners, when selected and used correctly, provide the necessary stability to ensure a safe and smooth driving experience.

Types of Fasteners Used in Automobiles

- Bolts and Screws: Bolts and screws are the backbone of automotive fastening. They come in various sizes, lengths, and thread patterns to accommodate different applications. From holding engine parts in place to securing body panels, bolts and screws serve a myriad of purposes.

- Nuts and Washers: Nuts are used in conjunction with bolts to create a secure joint. Washers distribute the load and prevent damage to the connected parts. They are essential in preventing loosening due to vibration.

- Rivets: Rivets are permanent fasteners that are often used in joining two or more metal parts. They are extensively used in automotive body assembly and provide excellent strength and durability.

- Clips and Retainers: Clips and retainers are used to secure various interior and exterior components, such as panels, trims, and electrical connectors. They enable easy assembly and disassembly for maintenance and repair.

- Threaded Inserts: Threaded inserts are used when a strong threaded connection is required in materials that cannot support threads directly. They are commonly used in applications involving plastics or composite materials.

Contributions to Automotive Safety

Fasteners directly impact the safety of vehicles and their occupants. Properly fastened components ensure that crucial systems such as brakes, suspension, and steering function as intended. Loose or improperly secured fasteners can lead to catastrophic failures, resulting in accidents. The rigorous standards set by the automotive industry demand precise torque specifications and quality control to prevent such mishaps.

Challenges in Fastener Design and Selection

Designing and selecting the right fasteners for automobiles is a complex process. Engineers must consider factors such as material compatibility, load-bearing capacity, corrosion resistance, and temperature variations. The fastener’s ability to withstand varying conditions over the vehicle’s lifespan is crucial for maintaining performance and safety.

Advancements in Fastener Technology

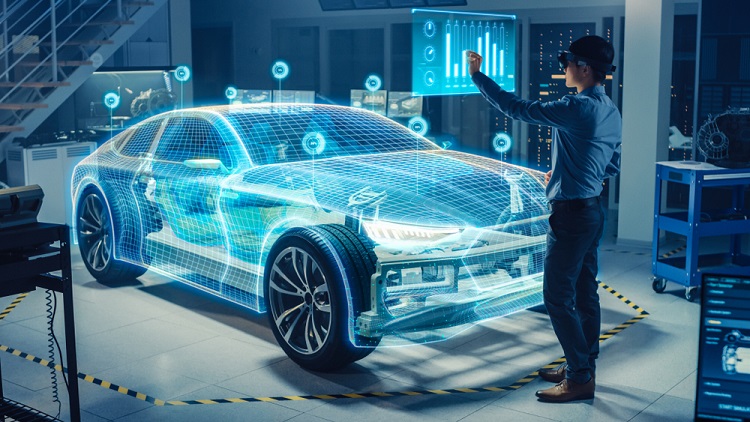

As automotive engineering evolves, so does fastener technology. Advancements include self-locking fasteners that resist vibration-induced loosening, lightweight materials for improved fuel efficiency, and coatings that enhance corrosion resistance. Moreover, the use of computer simulations and modeling aids in optimizing fastener designs for specific applications.

Conclusion

While often overlooked, fasteners are the linchpins of the automotive world. Their role in ensuring safety, performance, and durability is undeniable. As vehicles become more advanced and complex, fasteners continue to evolve to meet the demands of modern automotive engineering. The automotive industry owes a debt of gratitude to these unsung heroes that keep us moving forward, one securely fastened component at a time. Contact us for more information on the supplier of fasteners.